| 일 | 월 | 화 | 수 | 목 | 금 | 토 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| 25 | 26 | 27 | 28 | 29 | 30 | 31 |

- pump design standards

- plant operation and maintenance documentation

- foods that boost body temperature

- how to prevent colds with food

- definition and types of pumps

- tbe report preparation guide

- health benefits of chives

- difference between dynamic pumps and positive displacement pumps

- healthy winter snacks for warmth

- centrifugal pump working principle

- equipment data sheet and technical specifications

- pump applications and case studies

- types of industrial pumps

- environmentally friendly power plant

- design progress management

- ginger tea to raise body temperature

- honey for better circulation

- natural remedies for cold hands and feet

- features of different pump types

- warm-up foods for winter

- walnuts for winter health

- piping design standards

- radish for improving circulation

- piping stress analysis

- pump classification criteria

- key steps in vendor selection for epc contractors

- managing vendor print schedule in engineering projects

- pump operation methods

- vendor data requirement (vdr) review

- api standard pumps

- Today

- Total

Safety Balance

Piping Stress Analysis 본문

Piping Stress Analysis Overview

The purpose of piping stress analysis is to numerically verify the design safety of piping systems, ensuring compliance with design regulations and that the layout, support positions, types, and design requirements are met.

It involves demonstrating numerically whether the system remains within allowable stress ranges under various load conditions specified in the design standards and specifications, ensuring safe operation until the design lifespan is reached.

For piping systems transporting high-temperature fluids, the stress caused by thermal loads must be within the specified limits, and the layout should provide sufficient flexibility.

Comprehensive Piping Stress Analysis

In addition to static design against self-weight and thermal loads, piping systems should be designed to maintain integrity under dynamic conditions such as earthquakes and wind, ensuring economical operation.

The analysis must be performed using mathematical models for load or boundary conditions. Due to the complexity of calculations, numerical analysis using computer programs is employed to simulate actual operating conditions and verify the displacement and integrity of the piping under load.

Summary of Stress Analysis Tasks

- Detailed stress analysis to ensure integrity.

- Review whether the plant's characteristics or site-specific design requirements are met.

- Assess the safety of the piping against loads such as pressure, thermal expansion, self-weight, wind, and earthquakes.

- Verify whether connected equipment nozzles are subjected to excessive loads.

- Appropriately select the position and type of pipe supports and restraints.

- Check for potential interference with structures or other pipes due to thermal expansion or vibration.

- Implement scientific methods to achieve optimization rather than excessive design based on experience.

- Numerically verify the safety of the piping system and comply with relevant design codes.

Purpose of Piping Stress Analysis

- Application Standards and Criteria for Stress Analysis

- Apply ASME B & PV Code, Section I, ASME B31.1, or B31.3 standards as specified in the design basis.

- Classify piping into critical piping and general piping based on fluid energy density and system importance.

- Perform stress analysis for critical piping systems as required.

- Critical Piping Systems in Power Plants

- Main Steam System

- Boiler Feedwater System

- Heater Drain System

- Extraction Steam System

- Condensate System

- Piping systems with ANSI 900 lbs rating or higher, and design temperatures above 400℃.

Mandatory Stress Analysis

A. General piping systems that can be excluded from analysis.

B. Piping systems that can be approximated using simple calculations or graphical methods.

C. Piping systems requiring detailed review using dedicated analysis programs.

Major Targets for Stress Analysis in Power and Chemical Plants

- Key Targets for Analysis and Review

- Turbine Inlet & Outlet Piping

- Compressor and Blower Inlet & Outlet Piping

- Process Pump Suction & Discharge Piping

- Air Fin Cooler Inlet & Outlet Piping

- Fired Heater related Piping

- Reactor and Regenerator related Piping

- Jacketed Piping

- Additional Targets for Analysis and Review

- Piping with high risk of flange leakage.

- Piping handling hazardous materials classified as Fluid "M" Service.

- Major piping classified as high pressure (1500# or higher).

- Piping requiring regulatory approval.

- Non-metallic piping used in key processes.

- Piping connected to tanks or vessels with significant settlement.

- Piping expected to experience two-phase flow or impact loads.

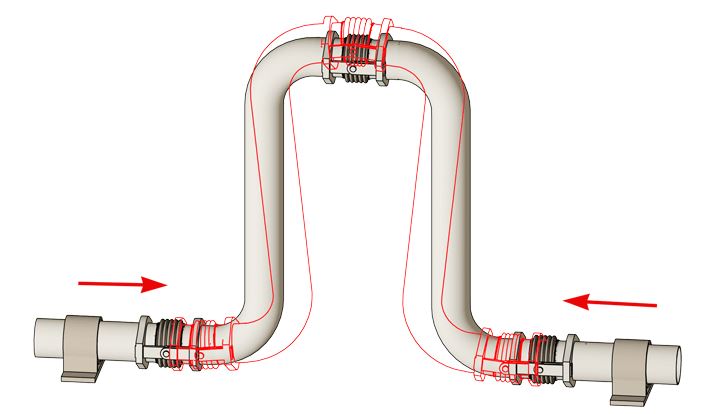

- Piping with expansion joints.

Related Data for Stress Analysis

- Process Flow Diagram (PFD)

- Reference temperature, pressure, flow rate, etc.

- Piping and Instrumentation Diagram (P&ID)

- Determine pipe size and insulation thickness.

- Piping Material Specification (PMS)

- Determine pipe size and insulation thickness.

- Equipment Drawing

- Review the location of connected equipment.

- Structural Drawings

- Confirm the position, height, direction, and size of structural members affecting pipe restraints.

- Piping Arrangement

- Determine the position, height, direction, and spacing of piping.

- 3D Piping Analysis Model

- Should include support points and be used for computer input.

'Technical' 카테고리의 다른 글

| Overview and Purpose of Piping Stress Analysis (0) | 2024.08.20 |

|---|---|

| "Standards Applied in Piping Design" (0) | 2024.08.06 |

| Method for Writing Piping Design Documents (0) | 2024.08.02 |

| Piping Design Document Preparation (0) | 2024.08.01 |

| TRAPS (0) | 2024.07.25 |