| 일 | 월 | 화 | 수 | 목 | 금 | 토 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| 25 | 26 | 27 | 28 | 29 | 30 | 31 |

- environmentally friendly power plant

- how to prevent colds with food

- definition and types of pumps

- centrifugal pump working principle

- walnuts for winter health

- vendor data requirement (vdr) review

- types of industrial pumps

- ginger tea to raise body temperature

- warm-up foods for winter

- pump operation methods

- honey for better circulation

- difference between dynamic pumps and positive displacement pumps

- api standard pumps

- natural remedies for cold hands and feet

- foods that boost body temperature

- tbe report preparation guide

- pump applications and case studies

- equipment data sheet and technical specifications

- key steps in vendor selection for epc contractors

- radish for improving circulation

- plant operation and maintenance documentation

- features of different pump types

- managing vendor print schedule in engineering projects

- design progress management

- healthy winter snacks for warmth

- health benefits of chives

- pump design standards

- piping stress analysis

- piping design standards

- pump classification criteria

- Today

- Total

Safety Balance

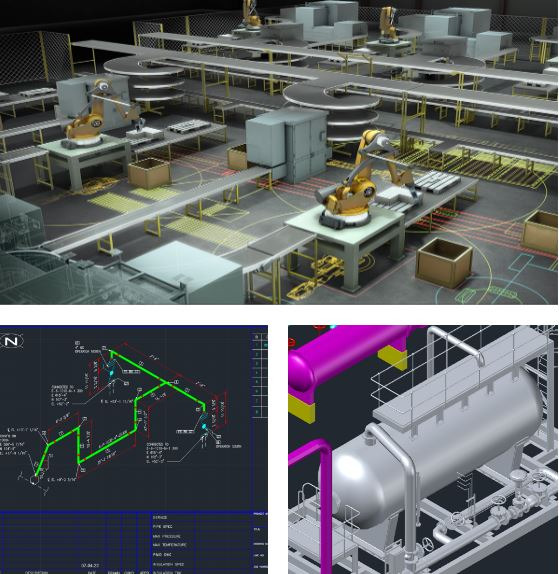

Piping Design Document Preparation 본문

Roles of the Piping Design Department

- Prepare design calculations for the piping system of the project

- Write specifications for the required design conditions

- Perform and review stress analysis of the piping system

- Approve selected equipment and conduct technical evaluations

Piping Design Organization

Definition of Piping Design

Piping design refers to the overall design process of connecting equipment using appropriate piping components according to the procedures specified by the process. It plays a crucial role in maintaining optimal operational performance and efficient plant operation. Designers must understand the extensive relationships related to the plant, acquire relevant theories and practical skills, and accumulate experienced proficiency.

Piping connects equipment to transport reaction media, raw materials, semi-finished products, or finished products within a plant. It consists of straight pipes, curved pipes, fittings, valves for flow control, etc. In piping systems transporting high-temperature fluids, stress occurs due to thermal loads. Such piping is constrained by nozzles or fixed points, which can lead to excessive reaction forces and stress accumulation, potentially causing failures. Therefore, piping must be designed with sufficient flexibility to ensure that generated stresses remain within allowable or specified limits.

Additionally, designers must establish close cooperation with process, design, civil, electrical, and instrumentation departments to carry out tasks within an overall timeframe.

Definition of Piping Design

In high-temperature fluid piping systems, stress occurs due to thermal loads. Such piping is constrained by nozzles or fixed points, which can lead to excessive reaction forces and stress accumulation, potentially causing failures. Therefore, piping must be designed with sufficient flexibility to ensure that generated stresses remain within allowable or specified limits.

Additionally, designers must establish close cooperation with process, design, civil, electrical, and instrumentation departments to carry out tasks within an overall timeframe.

Piping Design Process

Piping design significantly impacts performance and operability, so designers need to understand the organic technical system and the fundamental stance of engineering. It involves a complex interaction of system engineering, process engineering, piping engineering, and construction engineering.

Steps of Piping Design

Input Stage

- Basic Design: Consider environment and economic factors

- Planning Design: Suitability, safety, reliability

Output Stage

- Detailed Design: 90-95% of input details

- Design Revision and Changes: 100% of output details

Detailed Design Inputs and Outputs

Basic Design

- Line Schedule

- Plot Plan

Planning

- Routing Study

- Equipment Nozzle Orientation

- Civil & Structure Information

- Piping Study Drawing (Planning Drawing)

Detail

- Key Plan

- Arrangement Drawing

- Underground Piping

- Piping Support

- Steam Tracing

Design & Drawing

- Input -> Design

- Output -> Drawing

- Design calculations and drawing areas are strictly separated.

Approval of Design Documents

- For Approval: Request approval for completed design documents

- ANN (Approved As Noted): Conditional approval or approval with requested modifications

- AFD (Approved for Design): Approval for use in preliminary processes for design commencement

- AFC (Approved for Construction): Approval for commencement of construction based on design

'Technical' 카테고리의 다른 글

| Piping Stress Analysis (0) | 2024.08.06 |

|---|---|

| Method for Writing Piping Design Documents (0) | 2024.08.02 |

| TRAPS (0) | 2024.07.25 |

| STRAINER (여과기) (0) | 2024.07.23 |

| VALVES (2) (1) | 2024.07.22 |