반응형

Notice

Recent Posts

Recent Comments

Link

| 일 | 월 | 화 | 수 | 목 | 금 | 토 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| 25 | 26 | 27 | 28 | 29 | 30 | 31 |

Tags

- vendor data requirement (vdr) review

- environmentally friendly power plant

- definition and types of pumps

- piping stress analysis

- pump design standards

- honey for better circulation

- how to prevent colds with food

- features of different pump types

- centrifugal pump working principle

- piping design standards

- difference between dynamic pumps and positive displacement pumps

- tbe report preparation guide

- walnuts for winter health

- types of industrial pumps

- natural remedies for cold hands and feet

- radish for improving circulation

- healthy winter snacks for warmth

- plant operation and maintenance documentation

- foods that boost body temperature

- design progress management

- equipment data sheet and technical specifications

- warm-up foods for winter

- api standard pumps

- ginger tea to raise body temperature

- health benefits of chives

- pump classification criteria

- key steps in vendor selection for epc contractors

- pump applications and case studies

- pump operation methods

- managing vendor print schedule in engineering projects

Archives

- Today

- Total

Safety Balance

TRAPS 본문

반응형

Purpose of STEAM TRAP

- A steam trap is an automatic valve designed to efficiently use steam by distinguishing between steam and condensate using engineering principles and internal structures, and automatically discharging condensate.

Performance Level and Design Quality of STEAM TRAP

- It should be designed to remove the condensate generated from steam condensation in the steam space without leaking steam.

- It must be able to remove non-condensable gases such as air and CO2.

- It should operate correctly to ensure overall system performance and maintain energy savings.

- If condensate is not discharged smoothly, various problems can occur:

- Reduced effective heating area due to condensate accumulation in the steam pipes.

- Water hammering that can damage pipes.

- Corrosion of steam pipes, material aging, and shortened equipment lifespan.

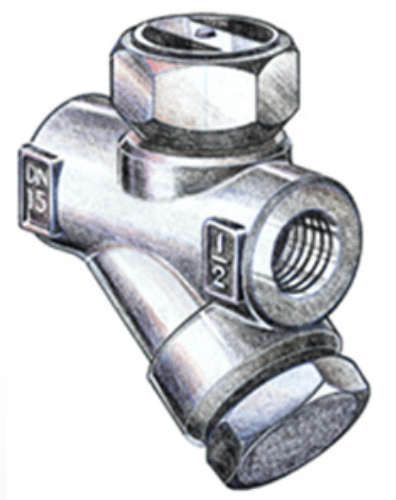

Thermodynamic TRAP

- Also called a disk trap as it operates with only one disk.

- Operates based on the speed difference between steam and condensate.

- Based on Bernoulli's principle: "In fluid flow, the total pressure (dynamic pressure + static pressure) is constant at all points. Thus, as the fluid speed increases, dynamic pressure increases and static pressure decreases."

Thermostatic TRAP

- Uses the temperature difference between steam and condensate to discharge condensate.

- Discharges condensate at temperatures lower than the steam saturation temperature, allowing the use of the sensible heat of condensate for energy savings.

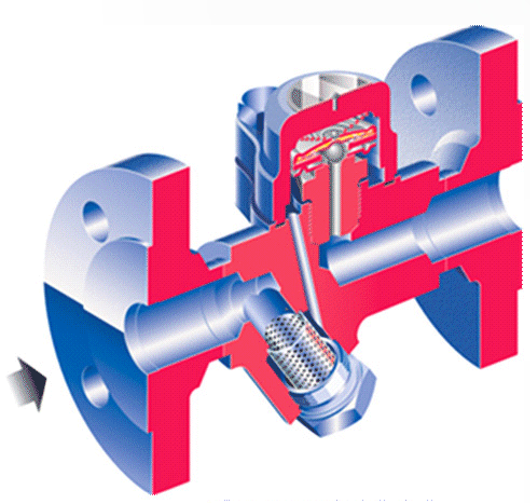

1) Balanced Pressure Trap

- The diaphragm element is protected by a thick stainless steel plate on the outside and consists of thin stainless steel plates that act as springs on the inside. Two diaphragms are welded to the thick outer stainless steel plate, and between these diaphragms and the outer protective plate, there is a liquid sealed that evaporates at a temperature slightly lower than the saturation temperature.

- A ball valve is welded to the center of the upper diaphragm.

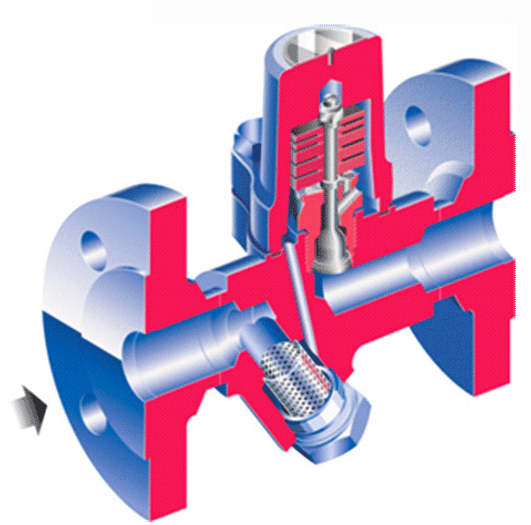

2) Bimetallic Type Trap

- Bimetal is made by joining two metals with different thermal expansion properties.

- When heated, bimetal bends to one side.

- A single bimetal is insufficient in capacity and operates at a constant temperature regardless of steam pressure, so several elements are combined to compensate.

- The discharge form of condensate changes according to the position of the valve.

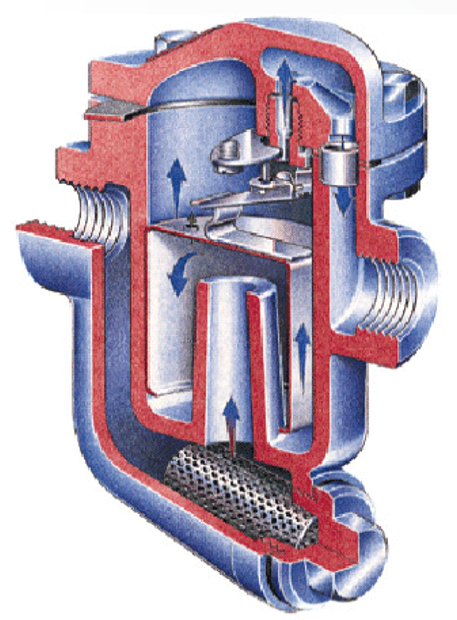

Mechanical TRAP

- Operates based on the difference in specific gravity (buoyancy) between steam and condensate.

- Discharges condensate almost simultaneously as it is generated.

- Types include Ball Floating Trap and Bucket Type Trap.

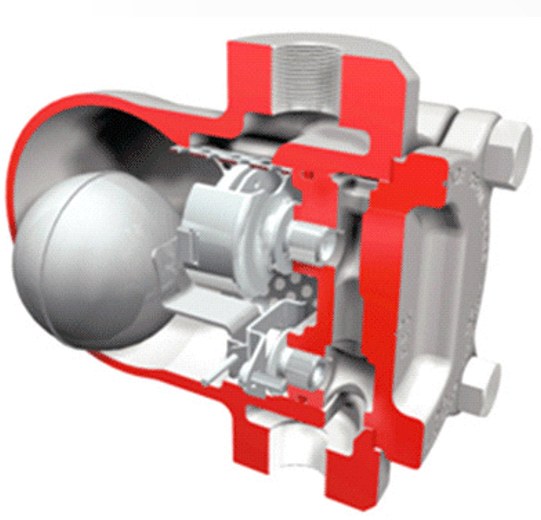

1) Ball Floating Trap

- A type of thermostatic trap.

- Operates with a ball float and lever.

- As soon as condensate enters the trap, the ball float rises due to buoyancy, and the valve opens, discharging the condensate.

- If air enters the trap, the float loses buoyancy and sinks, causing the valve to remain closed, leading to air binding.

- Most float traps have an integrated thermostatic air vent to remove unnecessary air.

2) Bucket Type Trap

- A type of thermostatic trap.

(1) Initial bucket

- Sinks, and the valve is fully open.

- Air enters the bucket through the inlet and gradually escapes through the vent hole.

(2) When air escapes

- Cold condensate enters the trap, filling the bucket inside and out.

- The bucket remains sunk, and the valve stays open, allowing condensate to discharge.

(3) When steam enters the trap

- Steam displaces the condensate inside the bucket and fills it, causing the bucket to rise due to buoyancy.

- The valve attached to the lever approaches the seat, and as condensate rapidly passes through the seat, the valve momentarily seals to the seat.

(4) As condensate continues to enter the trap

- Steam inside the bucket is pushed out through the vent hole, and some steam condenses, causing the bucket to lose buoyancy and sink, pulling the lever to open the valve.

- This cycle repeats, discharging condensate.

반응형

'Technical' 카테고리의 다른 글

| Method for Writing Piping Design Documents (0) | 2024.08.02 |

|---|---|

| Piping Design Document Preparation (0) | 2024.08.01 |

| STRAINER (여과기) (0) | 2024.07.23 |

| VALVES (2) (1) | 2024.07.22 |

| Valve (1) (0) | 2024.07.19 |