반응형

Notice

Recent Posts

Recent Comments

Link

| 일 | 월 | 화 | 수 | 목 | 금 | 토 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| 25 | 26 | 27 | 28 | 29 | 30 | 31 |

Tags

- vendor data requirement (vdr) review

- pump operation methods

- natural remedies for cold hands and feet

- difference between dynamic pumps and positive displacement pumps

- equipment data sheet and technical specifications

- piping stress analysis

- ginger tea to raise body temperature

- how to prevent colds with food

- warm-up foods for winter

- radish for improving circulation

- design progress management

- health benefits of chives

- centrifugal pump working principle

- features of different pump types

- piping design standards

- managing vendor print schedule in engineering projects

- foods that boost body temperature

- walnuts for winter health

- pump classification criteria

- plant operation and maintenance documentation

- types of industrial pumps

- healthy winter snacks for warmth

- api standard pumps

- environmentally friendly power plant

- definition and types of pumps

- honey for better circulation

- pump applications and case studies

- key steps in vendor selection for epc contractors

- tbe report preparation guide

- pump design standards

Archives

- Today

- Total

Safety Balance

Method for Writing Piping Design Documents 본문

반응형

▣ Line Schedule

- The piping system processes involve connections of numerous lines and equipment.

- The fluids flowing through these lines are categorized into various types.

- Each fluid is assigned a number and listed.

- Details such as fluid type, temperature, pressure, insulation, thickness, and operating conditions are recorded.

- This serves as an important guideline for piping design.

- It is created before the piping design document. Since it marks the starting and ending points of the design, cooperation with the process design team is essential.

▣ Plot Plan

- A drawing that shows the layout of all necessary equipment and facilities for the process.

- Allows subsequent piping design work based on the plot plan.

- A comprehensive layout drawing of the entire unit.

- It is the beginning and the entirety of the plant process.

- A critical factor in determining the hierarchy of the entire plant process.

- A preliminary technical document that serves as the basis for piping design input.

- The decision on the plot plan requires careful attention and numerous considerations

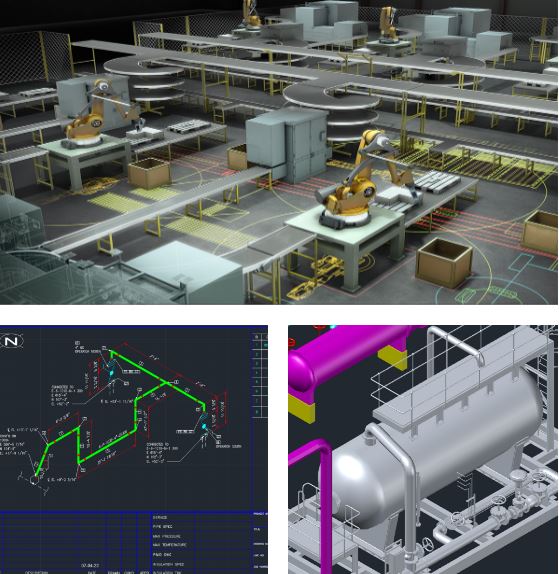

▣ Routing Study

- A basic working document for creating piping diagrams, i.e., detailed design drawings.

- The main layout of piping is roughly entered into the P&ID.

- Drawn to scale based on the piping concept diagram.

- A basic drawing for detailed design 3D modeling.

- Manual creation is common, and it is not a formal submission drawing.

▣ Detailed Tasks of Routing Study

- Determination of the spin for the main rack, calculation of loading data.

- Route determination for buried piping and study of stormwater and drainage.

- Electric cable and instrument duct study.

- Battery limit and firefighting study.

반응형

▣ Nozzle Orientation

- Layout drawings of nozzles and ladders for plant machinery and various equipment.

- A supplementary document prepared by the piping department and submitted to the machinery department.

- Generally, the elevation of nozzles cannot be arbitrarily adjusted.

- Only the angle of the nozzle is determined, with limitations on angle adjustments.

반응형

'Technical' 카테고리의 다른 글

| "Standards Applied in Piping Design" (0) | 2024.08.06 |

|---|---|

| Piping Stress Analysis (0) | 2024.08.06 |

| Piping Design Document Preparation (0) | 2024.08.01 |

| TRAPS (0) | 2024.07.25 |

| STRAINER (여과기) (0) | 2024.07.23 |